Meta:

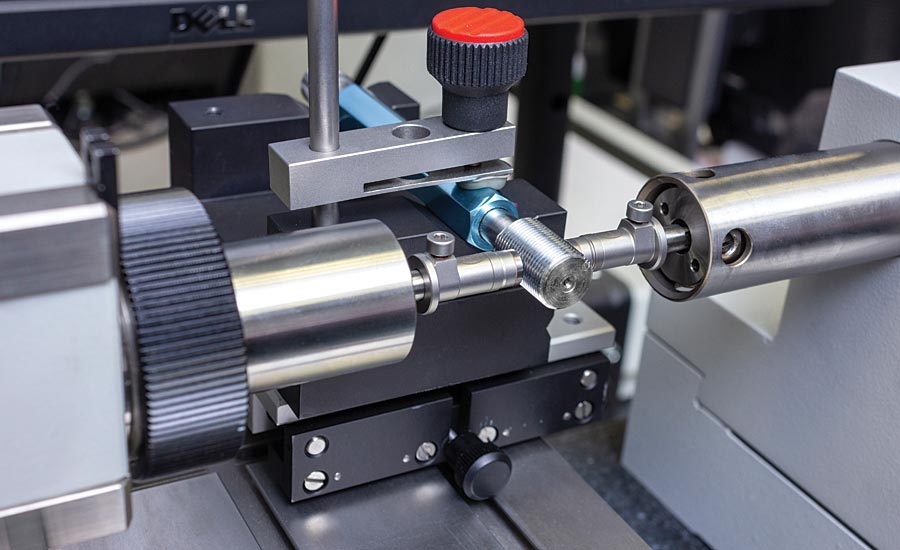

Image Filename: Simplex 0.9 –Fiber-Pigtail

Image Alt Text: fiber pigtails

In the realm of modern telecommunications and data transmission, fiber optics have revolutionized the way we connect and communicate. The backbone of this technology lies in the humble yet indispensable fiber pigtail, an often-overlooked component that has undergone a remarkable evolution over the years.

This guest post retraces the developmental journey of fiber pigtail technologies from their basic beginnings to their advanced iterations, highlighting their crucial role in enabling high-speed data transmission and telecommunications.

The Birth of Fiber Pigtails

Fiber optic technology dates back to the 1960s when scientists and engineers first explored the possibility of transmitting data using light signals through hair-thin strands of glass or plastic fibers.

These early optical fibers had many limitations, including high signal loss due to impurities in the glass and poor light-guiding capabilities. Fiber pigtails emerged during this period as a means to facilitate the connection between optical fibers and other components of the system, such as lasers, detectors, and connectors.

The Early Days: Simple Fiber Pigtails

The earliest fiber pigtails were rudimentary in design, comprising a bare optical fiber attached to a connector. These connectors were typically made of ceramic or metal and were often hand-polished to ensure a minimal loss of signal during transmission. The early fiber pigtails were challenging to handle and susceptible to damage, making them unsuitable for widespread use.

As the demand for more reliable and efficient optical communication systems grew, so did the need for improved fiber pigtail technologies. The first significant advancement came in the form of epoxy-based connectors, which provided better protection for fragile optical fibers and reduced signal loss. Epoxy connectors quickly gained popularity and became the industry standard for many years.

Single-Mode vs. Multi-Mode Pigtails

As optical fiber technology continued to advance, the need for greater data transmission capacity and longer-distance communication became evident. This led to the development of single-mode and multi-mode fiber pigtails, each optimized for specific applications.

Single-mode fiber pigtails, characterized by their thin cores and minimal signal dispersion, became the preferred choice for long-distance communication. They offered significantly lower signal loss compared to multi-mode fibers, making them ideal for applications like telecommunication networks and high-speed data transmission.

On the other hand, multi-mode fiber pigtails, with their larger cores, were well-suited for short-distance applications within data centers and local area networks (LANs). While they couldn’t match the performance of single-mode fibers over long distances, they offered cost-effective solutions for many businesses.

The Advent of Fusion Splicing

One of the most significant breakthroughs in fiber pigtail technology was the development of fusion splicing in the late 1970s. Fusion splicing allowed two optical fibers to be precisely aligned and permanently joined, minimizing signal loss and ensuring a seamless connection. This technique marked a significant improvement over epoxy-based connectors, which often had higher losses and were susceptible to environmental factors.

Fusion splicing not only improved the performance of fiber pigtails but also made them more reliable and durable. It became the standard method for connecting optical fibers, enabling the deployment of high-speed, long-distance communication networks.

Miniaturization and Connectors

The 1990s brought about further advancements in fiber pigtail technology, driven by the demand for smaller and more versatile connectors. Miniaturization became a key focus, leading to the development of smaller connectors, such as the SC and LC connectors. These connectors, with their reduced form factors, allowed for higher-density installations in data centers and telecommunications equipment.

Additionally, connectors with push-pull mechanisms and improved latching mechanisms made it easier to connect and disconnect fiber pigtails, reducing the risk of damage during installation and maintenance.

Enhanced Protective Coatings

To address concerns about the durability of fiber pigtails, manufacturers began incorporating enhanced protective coatings in the late 1990s. These coatings were designed to withstand harsh environmental conditions, including moisture, temperature fluctuations, and physical stress. The addition of robust coatings significantly extended the lifespan of fiber pigtails, making them suitable for outdoor installations and industrial environments.

The Present: Advanced Fiber Pigtail Technologies

Today, fiber pigtail technologies have reached a level of sophistication that was once unimaginable. They are now an integral part of a wide range of applications, from high-speed internet connections to telemedicine and beyond.

Advanced materials, including low-loss optical fibers and high-quality connectors, have reduced signal loss to near-zero levels. This has enabled the deployment of ultra-fast data transmission systems, making it possible to stream high-definition video, engage in real-time virtual meetings, and transfer vast amounts of data at speeds measured in gigabits or even terabits per second.

Furthermore, the ongoing development of fiber pigtail technologies continues to push the boundaries of what is possible. Researchers are exploring new materials, such as hollow-core fibers, which promise even lower signal loss and greater bandwidth. These innovations hold the potential to revolutionize various industries, including telecommunications, healthcare, and scientific research.

The evolution of fiber pigtail technologies from their basic beginnings to their advanced iterations is a testament to human ingenuity and the relentless pursuit of better, faster, and more reliable communication systems. From simple connectors to fusion splicing, miniaturization, enhanced coatings, and beyond, fiber pigtails have come a long way in a relatively short time.

So, if you’re looking to buy the latest fiber pigtails, Fibermart is your best option for it. Fibermart, a global company with operations in both Hong Kong and the United States, stands at the forefront of the fiber optic network supply industry. Their extensive product lineup encompasses Polarization Maintaining Fiber Cable, Polarization Maintaining Splitter, Polarization Maintaining Coupler, and a lot more. Contact them today and learn more about their solutions.